Hot working system retrofit: shell – WU292/WU293 (refurbishment)

Date: 2023 to 2024

Contracting entity: BMW Group

End customer/site of installation: BMW Dingolfing

Plants such as:

WU292/oven (refurbishment) | WU292/press (refurbishment) | WU293/oven (refurbishment) | WU293/press (refurbishment)

Project description:

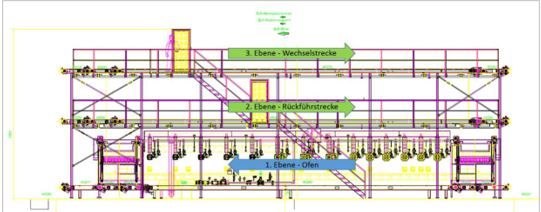

Car body parts are hardened on two identical systems WU292 and WU293. For this purpose, the cold-pressed components are heated in a continuous furnace and systematically cooled in a tool in the press. Measures to maintain the substance of the electrical components of the conveyor lines are being carried out at both plants. For this, cables and components are renewed, parts are brought up to date and recommissioned.

- Entire electric planning (hardware construction, software project planning)

- Control cabinet construction, air conditioning, and SEW inverter adjustment

- Provision of burner control units

Technologies (excerpt):

8pieces S7-400 with CPU 416 | 8pieces visualization Zenon 7.60 | 56pieces burner control units | 20 pieces Rittal cooling systems Blue e+ | 60pieces SEW inverters on MOVI-PLC